Learn about wheel alignment, its importance, common issues, necessary tools, and how to perform proper alignment for optimal vehicle performance and safety.Welcome to our comprehensive guide on wheel alignment in Car Mechanic Simulator! In the dynamic world of vehicle maintenance, understanding the nuances of wheel alignment is crucial—not just for realism in the game, but also for enhancing your skills as a virtual mechanic. Proper alignment impacts tire wear, handling, and overall vehicle performance, making it an essential aspect of car maintenance. Throughout this blog post, we’ll delve into the fundamentals of wheel alignment, explore its importance, identify common issues mechanics face, and outline the equipment and tools you’ll need to get the job done effectively. Finally, we’ll provide a step-by-step guide on performing wheel alignment in the simulator. So, let’s get started and fine-tune your mechanics expertise to ensure precision and efficiency in every virtual repair!

Understanding Wheel Alignment

Wheel alignment is a pivotal aspect of vehicle maintenance that ensures your car drives straight and true. It involves adjusting the angles of the wheels so that they are set to the manufacturer’s specifications. Proper alignment is essential for maximizing tire life, enhancing fuel efficiency, and improving overall vehicle handling.

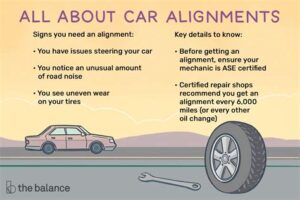

When the wheels are misaligned, it can lead to uneven tire wear, which shortens the tire’s lifespan and may cause additional operational issues. A vehicle with a bad wheel alignment may pull to one side while driving, resulting in a less safe driving experience. Visual clues such as uneven tire wear or a crooked steering wheel can indicate that your car may require alignment adjustments.

In a typical wheel alignment process, several elements are taken into account, including the camber, caster, and toe angles. These angles play a significant role in how the tires interact with the road. The camber measures the inward or outward tilt of the tire; the caster refers to the angle of the steering axis; and the toe indicates whether the tires are pointed inward or outward.

Importance of Proper Alignment

Proper alignment of your vehicle’s wheels is essential for maintaining optimal performance and safety on the road. When your wheels are correctly aligned, it impacts not only the handling of the car but also the longevity of your tires. Misalignment can lead to uneven tire wear and can create other mechanical issues that can be costly to repair.

Furthermore, a well-aligned car contributes significantly to fuel efficiency. According to studies, improperly aligned wheels can decrease your vehicle’s fuel economy by increasing drag and hindering smooth operation. This means you could be spending more money on fuel than necessary due to poor alignment.

Another important aspect of proper wheel alignment is driver comfort. A vehicle that is out of alignment often pulls to one side or requires constant steering adjustments, resulting in a less pleasant driving experience. Therefore, ensuring your wheels are properly aligned can greatly enhance the overall driving experience, making it safer and more comfortable.

Common Wheel Alignment Issues

When it comes to the performance and safety of your vehicle, proper wheel alignment plays a crucial role. Over time, you may experience various issues that can compromise this alignment. Here are some of the most common wheel alignment issues drivers face:

- Uneven Tire Wear – Misalignment often leads to tires wearing unevenly. This not only affects the longevity of your tires but can also lead to unsafe driving conditions.

- Pulling to One Side – If your vehicle tends to drift or pull to one side when driving on a straight road, it’s likely a sign that your wheels are misaligned.

- Steering Wheel Off-Center – A steering wheel that is not centered can indicate a misalignment. When you notice this issue, it’s essential to get a professional assessment.

- Vibration or Shaking – If you feel vibrations or shaking in the steering wheel at higher speeds, it could be due to poor alignment or related suspension issues.

- Increased Fuel Consumption – Proper alignment helps your vehicle run efficiently. Misalignment can lead to increased rolling resistance, causing the engine to work harder and thus consuming more fuel.

Recognizing these common issues is the first step toward ensuring your vehicle is safe and efficient. Schedule regular checks for wheel alignment to maintain the integrity of your car and prevent costly repairs.

Visiting a professional mechanic can provide you with the necessary insights into the state of your wheel alignment and help you address any problems that may arise.

Remember, regular maintenance of your vehicle, including wheel alignment checks, is essential for not only enhancing performance but also ensuring the safety of you and your passengers on the road.

Wheel Alignment Equipment and Tools

Proper wheel alignment is crucial for vehicle safety, tire longevity, and overall performance. To achieve optimal alignment, specific equipment and tools are necessary to ensure accuracy and efficiency. In this section, we will delve into the various tools and technologies used in wheel alignment practices.

1. Alignment Lift: This is an essential tool that provides a stable platform for raising the vehicle off the ground. It enables mechanics to access the wheel assembly easily. Many alignment lifts are designed with built-in alignment racks to streamline the process.

2. Wheel Alignment Heads: These precision instruments are placed on each wheel to measure the alignment angles accurately. They can be digital or optical and provide real-time data to the mechanic, allowing for quick adjustments as needed.

3. Camber Gauge: This tool measures the tilt of the wheel from vertical. A proper camber measurement is critical to ensuring that tires wear evenly and perform well under various conditions. This gauge helps to determine the correct angle to set.

4. Turntables: Used in conjunction with alignment heads, turntables allow the wheels to pivot while measurements are taken. This is particularly useful for adjusting the steering angles and ensuring that the toe is set accurately.

5. Diagnostic Software: Advanced wheel alignment systems now incorporate software that helps analyze data from the alignment heads. This technology provides detailed reports and recommendations for any adjustments needed.

6. Torque Wrench: This tool is crucial for applying the correct torque when tightening suspension components after alignment adjustments. It ensures that all bolts are correctly tightened to specifications, which is essential for safety.

Having the right equipment and tools is essential for effective wheel alignment services. By utilizing these tools, mechanics can achieve precise measurements and make necessary adjustments, ensuring that vehicles are safe and perform well on the road.

How to Perform Wheel Alignment

Performing wheel alignment is a crucial task for maintaining the longevity and performance of your vehicle. Proper alignment ensures that your tires wear evenly, enhances fuel efficiency, and improves the vehicle’s handling characteristics. Below are the steps to effectively perform wheel alignment.

Step 1: Prepare the Vehicle

- Ensure that the vehicle is on a flat surface.

- Check tire pressure and ensure that all tires are inflated to the manufacturer’s specifications.

- Inspect the suspension components for any wear and damage. Replace any faulty parts before alignment.

Step 2: Set Up the Equipment

To perform alignment, you will need the following tools:

- Alignment machine or laser alignment tool

- Adjustable wrenches

- Torque wrench

Step 3: Measure Wheel Angles

Once the vehicle is prepared, position the alignment machine and take initial measurements of the camber, caster, and toe angles. Compare these measurements against the manufacturer’s specifications.

Step 4: Adjust the Angles

If the measurements are out of spec, use the adjustable components to correct the angles:

- Adjust the toe settings using the tie rods.

- Modify the camber by adjusting the upper control arms.

- Change the caster angle if necessary by adjusting the lower control arms.

Step 5: Final Measurement and Test Drive

After adjustments, re-measure the angles to ensure they are within specifications. Finally, test drive the vehicle to confirm that it handles properly and the steering is aligned.

Pro Tip: Regularly check your wheel alignment every 6,000 miles or as needed to avoid issues.

Frequently Asked Questions

What is wheel alignment in a car simulator?

Wheel alignment refers to the adjustment of a vehicle’s suspension components to ensure that the wheels are positioned correctly relative to each other and the road.

Why is wheel alignment important in car mechanics?

Proper wheel alignment ensures even tire wear, improves handling, enhances fuel efficiency, and provides a more comfortable driving experience.

How does a car mechanic simulator teach wheel alignment?

A car mechanic simulator provides virtual tools and scenarios for users to practice measuring and adjusting wheel angles such as camber, toe, and caster.

What are common signs that a vehicle may need wheel alignment?

Common signs include uneven tire wear, the car pulling to one side, a crooked steering wheel, and vibrations in the steering wheel.

What tools are typically used for wheel alignment in a simulator?

Tools include alignment racks, computerized alignment systems, tread depth gauges, and adjustable suspension components.

Can a wheel alignment be performed at home using a simulator?

While a simulator can teach the principles and processes of wheel alignment, actual adjustments require specialized equipment and training.

What benefits can players expect from practicing wheel alignment in a simulator?

Players can expect to enhance their understanding of vehicle dynamics, improve their mechanical skills, and gain confidence in performing real-world alignments.